This blog post is dedicated to the lumber nerds out there. And if you aren't a lumber nerd, we hope you'll learn something.

Lumber cut styles are cuts that are made when milling logs into usable building materials. The four cut styles we'll look at here are live sawn, plain (or flat) sawn, quarter sawn, and rift sawn.

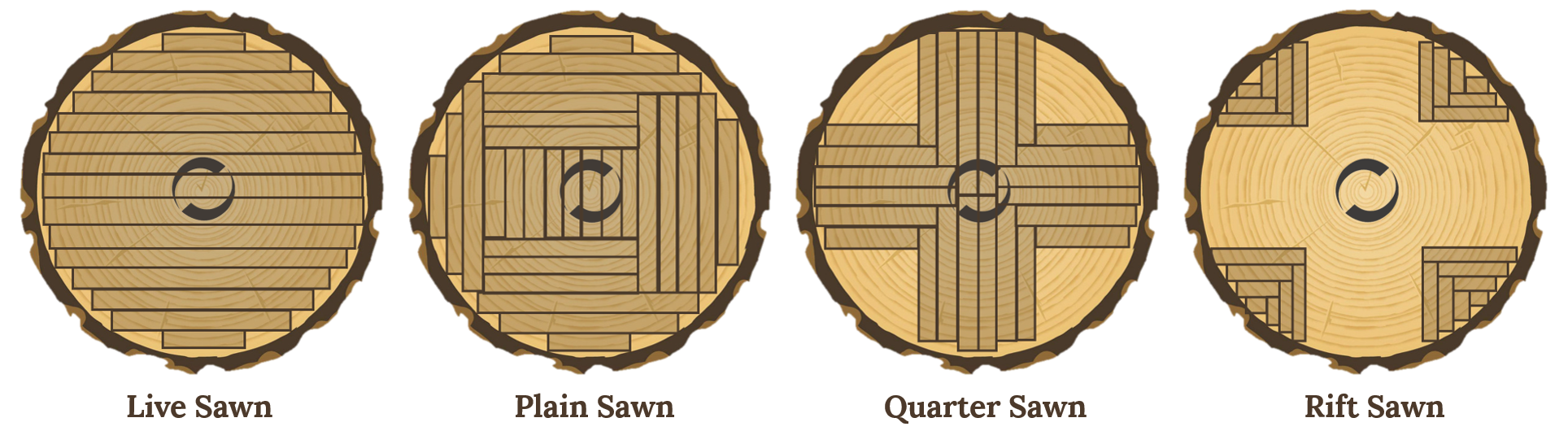

Let's visualize how a log is cut into dimensional lumber. In the late 19th and early 20th centuries, logs were milled by moving the log over a large circular saw blade. However, most modern dimensional lumber is cut on a sawmill that is made up of a large horizontal band saw which moves while the log is locked into position. Each cut style is accomplished by by cutting the the log in varying directions. The graphic below shows the resulting end grains.

Notice the grain pattern in each of these cut styles. Live sawn is how you produce live edge slabs and it is the simplest way to mill a log. The plain sawn is a cross section of the log and has a varying grain pattern, recognizable by its characteristic �cathedral� grain on the surface. Quarter sawn boards are cut so that a vertical grain pattern is visible on both the top and bottom of the board. Rift sawn boards are cut so that all four sides of the board have a vertical grain pattern.

The durability and stability of the lumber is determined by the cut style. Plain sawn material, because of how the grain runs through it, is the least stable of the three, and the most likely to cup or crown as it dries. Quarter sawn material is much more resistant to movement and is a common choice for hardwood flooring. Rift sawn has a similar stability to quarter sawn, but gives the material more strength, so this style is often used in furniture building, namely table and chair legs.

The price of each of these cut styles is directly related to the amount of waste involved in cutting them. The live sawn cut produces the least amount of waste, as the boards are cut in cross sections all the way through the log. The waste amount increases with each style in the graphic. Generally, the live sawn cut is the least expensive, while rift sawn is usually the most expensive.

The next time you are in the market for new hardwood floors, or wood for your kitchen countertops, you will know what the different lumber cut styles are, how they will affect your price, and the longevity of your product.